에코를 선택한 이유

혁신이 미래를 이룰 수 있다고 믿습니다.

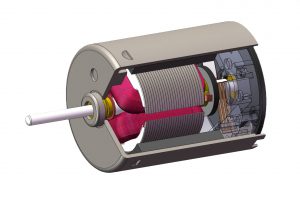

자동차 산업을 예로 들면, 이 분야를 위해 각종 모델의 모터를 제조합니다.

R276입니다.

더 높은 수준의 시장 요구에 부합하기 위해 R276 모델 모터를 개발하여 새로운 업계 지표를 수립했습니다.

다음은 업계에서 에코의 경쟁 우위입니다.

소음-진동-수명-외관

6 poles motors can further reduce no load speed compared to traditional 3 poles motors, producing minimal frictional and mechanical noise. Technically, the noise level of 6 poles motors is lower than that of 3 poles by 3-4 dB.

6 poles armature creates a balanced copper winding rotor core. Higher dynamic balancing and lower vibration during rotation.

Our metal housing case and end plate are securely stamped together. Results?

Our motors can withstand as much as 200N axial impact force and work up to 5000 hours depending on loaded speed and torque.

Shape is of paramount significance to the performance of a motor. A round shape allows an even distribution of magnetization that gives smooth transaction of magnetic poles during rotation. These mean lower noise and less vibration, and ultimately, better user experience.

1 . 코깅 토크△K 비교

R276

average

△K

0

Competitor

average

△K

0

에코R276모터는 코깅 토크가 현저히 더 낮음, 에너지 전환 효율이 더 높음.

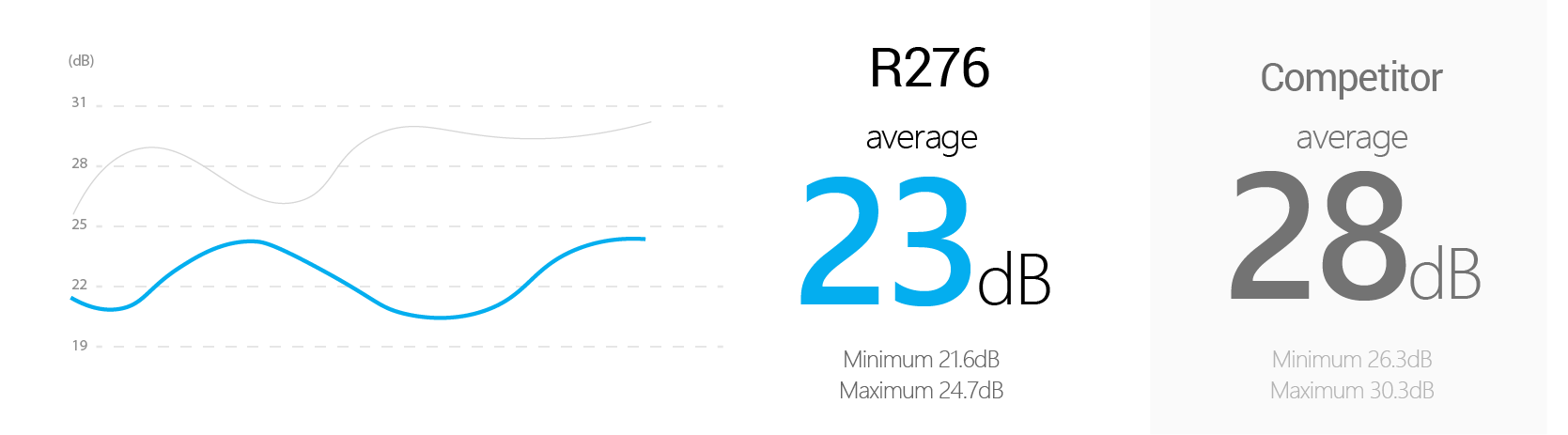

2 . 소음치 (dB)비교

에코 R276 모터의 소음치(평균 23㏈)는 업계 평균치보다 낮음(28㏈)

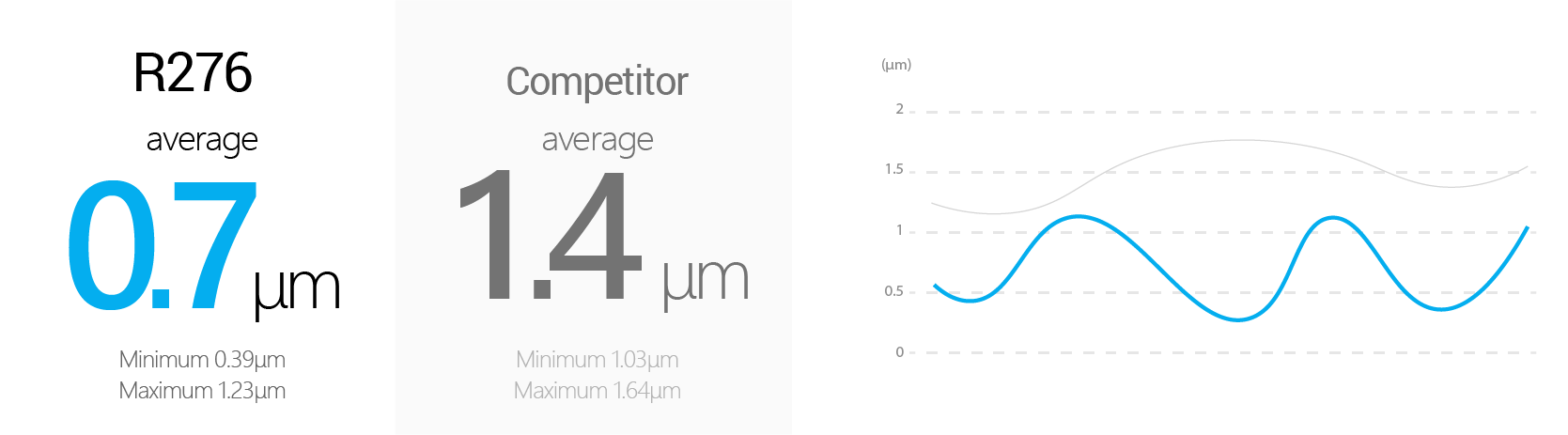

3 . 진폭 비교

에코모터는 진폭이 더 낮음